Bottom of the Barrel Upgrading

LC-FINING / LC-MAX

LC-FINING

Convert LC-FINING technology to LC-MAX technology or Hybrid SLURRY.LC-FINING efficiently hydrocracks residuum to high-quality fuel oils and transportation fuels.

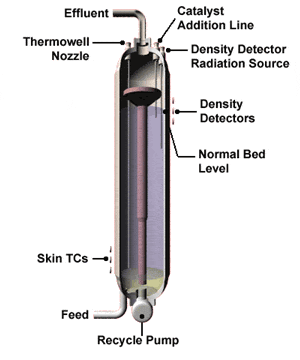

LC-FINING is CLG’s ebullating bed residue hydrocracking process, which provides high conversion of residues selectively to liquid products and high removal of metals, sulfur and CCR from difficult feedstocks. LC-FINING provides this superior performance with ease, safety and reliability at the best economics. Only CLG LC-FINING can reduce both capital investment and operating expenses. Its built-in onstream catalyst addition and withdrawal system eliminates the need to shut down for catalyst replacements. The proprietary low pressure hydrogen recovery system eliminates most high pressure equipment required in other processes.

Key Advantages:

• Low investment• More light-ends recovery

• Lower operating costs

• More efficient heat recovery

• Lower hydrogen losses

• Lower maintenance

• Maximum conversion to light clean products

• Integrated fuels hydroprocessing

• Four years operation between turnarounds

LC-FINING treats heavy hydrocarbons with hydrogen in the

presence of catalyst to produce low sulfur products.

LC-MAX

LC-MAX is a unique flow scheme advancement to LC-FINING that integrates a solvent deasphalting section into the LC-FINING flow scheme, the result of which is achieving more than 90 percent conversion with high product selectivity.CLG also offers solutions for converting LC-FINING to LC-MAX or Hybrid SLURRY.