Improved Product Yields — Improved Profit Margins

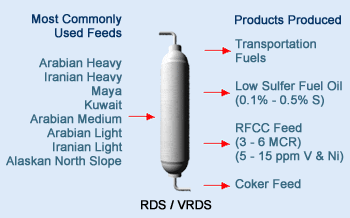

CLG’s fixed bed residuum hydrotreating technologies, RDS for atmospheric residuum hydrotreating and VRDS for vacuum residuum desulfurization, are leading technologies that provide short, economical process paths to higher value products from difficult feeds. Only CLG’s hydrogen-efficient RDS/VRDS technologies sufficiently saturate products so that no further processing is necessary when using residuum as the feed for high-value light products. Less processing leads to better profit margins now, and in the future.

Using CLG’s residuum hydroprocessing technology, refiners

can produce high-quality products from almost any crude.

Increase RFCC Profit by Adding RDS

Residuum Fluid Catalytic Cracking is the most popular processing route for the complete conversion of residual oils. Refiners without a pretreating system in place must process atmospheric residuum from crudes low in metals, carbon residue and sulfur to avoid operating problems.

Consequently, many refiners have chosen to pretreat their RFCC feed in a CLG RDS/VRDS reactor. By doing so, they have more flexibility in choosing less expensive feeds, achieve higher product yields and have fewer feed-related operating problems. CLG’s technology has been used successfully to improve the efficiency of every type of RFCC unit in operation today.

Heavy Feeds to High-Value Products Takes Just the Right Catalyst

Converting heavy feeds into high value light products is a challenge for any processing scheme. CLG’s fixed bed technology provides a premium solution due to the sophistication and quality of its catalyst grading system. The efficiency of every unit can be enhanced if a thorough analysis of feed characteristics relative to operating kinetics and chemical reaction is understood.

With our extensive commercial experience and pilot plant data, we can develop catalyst systems that will meet the most demanding quality objectives while processing very difficult feeds. As a result of the extraordinary quality of these systems, operating cycles are usually extended while meeting target specifications for demetalization, desulfurization, carbon residue reduction, denitrification and increased cracking conversion.